SC3 Automation and NVIDIA partner to enable the Jetson AGX Xavier Industrial safety capability. Autonomous machines, Industrial and Rail application can leverage the power of the JAXi for intensive data processing functions such as Sensor Fusion and Artificial Intelligence in combination with SC3 Automation's proven Safety MCU and IO boards.

The SENFAI is a modular safety-related controller board combining a safety MCU, a communication

co-processor, and designed to host the safety-capable NVIDIA Jetson JAXi Industrial SOM (SENFAI will support Jetson once released). The safety MCU processor is used to implement safety functions.

When combined with a safety IO board or remote sensors and actuators, the SENFAI safety contoller can perform safety functions. The safety performance level of the safety functions combining the use of the JAXi depends on the application and the features used.

Set two SENFAI safety controllers in a network such that the two safety MCUs meet SIL 4 according to EN 50129. The SENFAI can also be placed in a network with SC3 Automations SC3Node (SIL 3/ASIL-D) and/or SC4Node (SIL 4 according to EN 50129) controllers.

The SENFAI controller is designed to support safety functions with SIL 3 according to IEC 61508:2010, Ple cat. 4 according to ISO 13849, and ASIL-D according to ISO 26262. The SENFAI is designed to be used in various markets. It is compliant to Railway, Automotive and Industrial markets.

The SENFAI controller is available in various hardware configurations with or without IO boards. The available types of IO boards are the SC3 Automation Universal Digital IO, Universal Digital IO Double-cut, Universal Analog IO and the specialized transportation/rotating machinery Relay IO (with Quadrature encoders/pulse counters).

The SENFAI controller supports CAN, RS-232, RS-422, and RS-485 half-duplex and full-duplex communication. Industrial communication ports enable the use of the Ethernet protocols such as EtherCAT®, and Ethernet/IP™, ProfiNet™. The SENFAI controller includes temperature monitoring that detects an under temperature and triggers a heater circuit, an over temperature that initiates a system safe state.

The SENFAI has one SIL 3 Master Disconnect Output to signal the safe state when there are no IO boards. From a laptop, access the SENFAI embedded web server to configure the required parameters and set the real-time clock. Also, monitor and access application data, update the application, and access the system log.

The Jetson AGX Xavier Industrial (JAXi) system on module coupled with the Jetson Safety Extension Package (JSEP) provides the foundation for fault avoidance, detection, and control in safety-related systems. The hardware infrastructure for fault detection and control is implemented in the Xavier SOC on the JAXi module. NVIDIA JSEP software running on top of the NVIDIA JetPack™ SDK exposes that infrastructure for use in customer-defined systems.

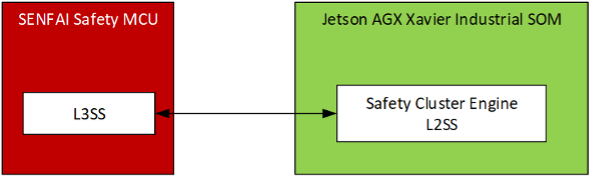

The SENFAI implements the safety MCU Interfaces as described in the JAXi documentation. JAXi uses some of the existing signals to interface with a safety MCU if, implemented in a design. This includes:

In addition, several other interface pins that were not supported on JAX or JAX 64GB are available to interface with the safety MCU including:

NVIDIA Jetson AGX Xavier Industrial module includes the Xavier SOC which is TÜV SUD assessed for meeting all applicable requirements for ISO 26262. The module also includes various built-in safety extensions:

The SENFAI supports the JSEP including the 3LSS mechanism to perform monitor and error reporting from JAXi. The Jetson Safety Extension Package provides error diagnostic and error reporting framework for implementing safety functions and concepts to achieve functional safety standard compliance. Features:

The safety performance level achievable for an application implemented on the JAXi depends on a number of factors including the selected architecture, the operating system, and the components used. Each application requirement needs to be reviewed. SC3 Automation can assist customers to determine the appropriate safety strategy for a given application.

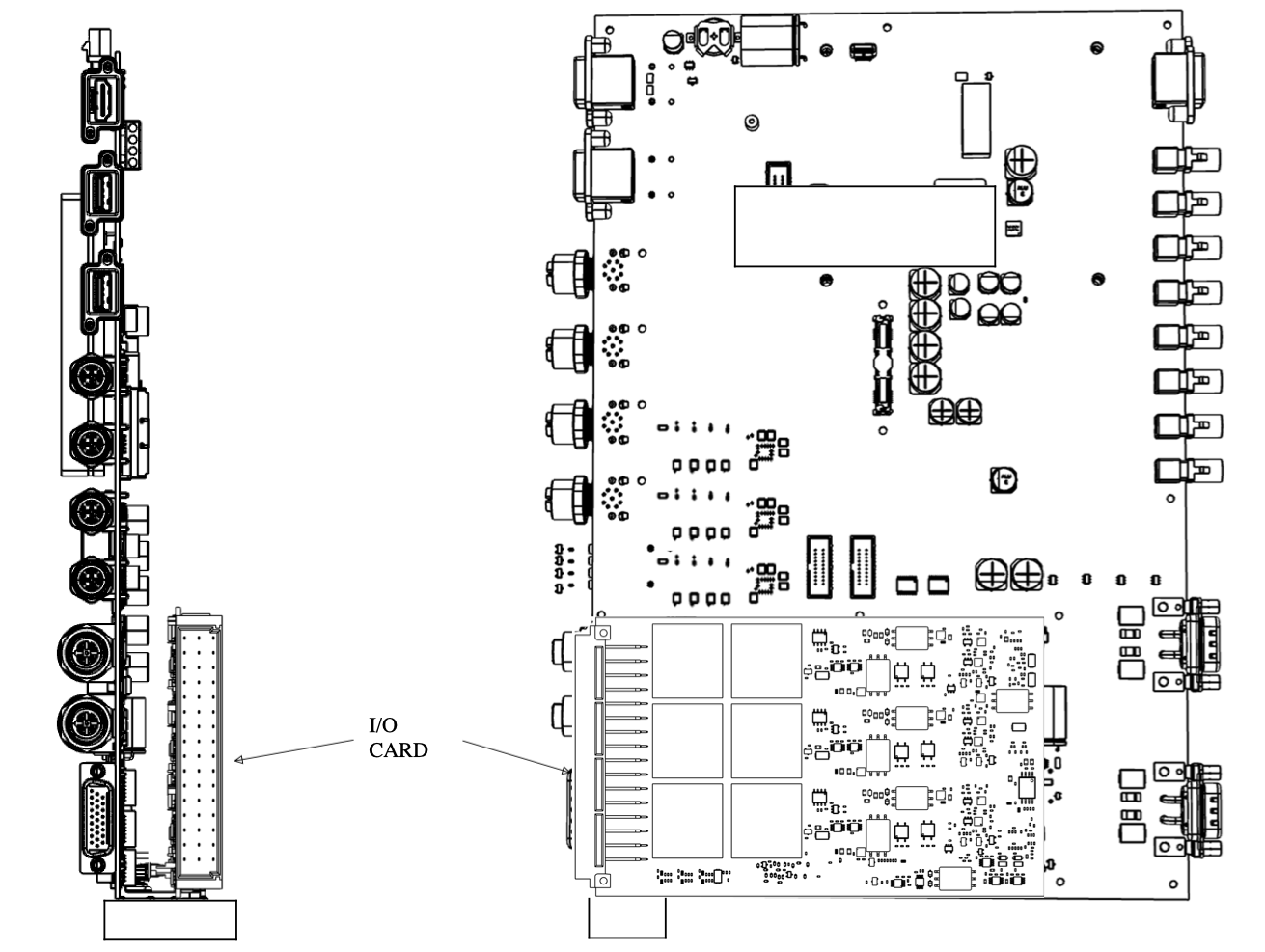

The SENFAI offers a rich set of features and is ready to use. SC3 Automation’s mission is to provide customers with safety controllers that meet their exact requirements. Customization of the SENFAI including the number of peripherals, the type of connectors, the type of enclosure is performed to fit the exact needs of the application. The SENFAI extended design has a variety of connections to various peripherals. The image below shows the front and back view of the different connectors.